Versatility of Changjianshun truss connectors

Introduction to Changjianshun Truss Connectors

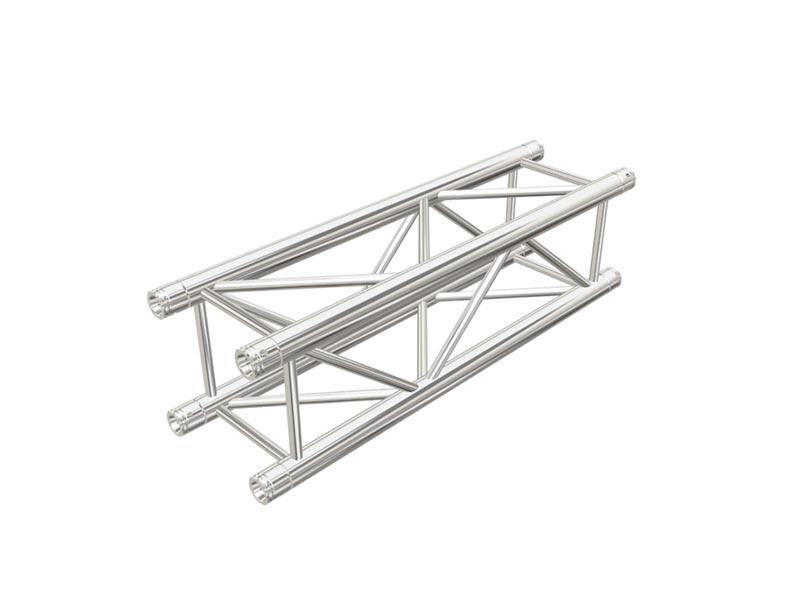

In construction, truss connectors play a vital role by joining different truss members. Most commonly fabricated from steel or similar durable materials, these connectors do what their name suggests keep everything connected properly. Their main job is to hold truss systems together so they don't fall apart under stress. Without them, all those individual pieces wouldn't work as a team to support heavy loads. We see this in action every day when looking at buildings with flat roofs or multi-level flooring systems. Properly installed connectors make sure these structures stay standing through all sorts of weather conditions and daily wear and tear.

Truss connectors matter a lot in construction work. These components help spread out the weight across different parts of a building frame, which keeps things stable instead of letting them shift around or get damaged as seasons change. When installed properly, these connectors make all the difference for how strong a structure stands up against wind, snow loads, or earthquakes. That's why most professional builders consider good quality truss connectors essential when designing anything from small sheds to large commercial buildings. Without proper connections between those wooden beams, even minor stress points can lead to major problems down the road.

Types of Truss Connectors

Truss connectors come in all sorts of shapes and sizes, tailored for different jobs on site. Their main job? To hold those truss pieces together so nothing falls apart during construction or after the building is complete. Without good connectors, whole sections could collapse under their own weight or from wind loads. We see them everywhere from single family homes going up in neighborhoods to massive warehouses and shopping centers across town. Picking the right type matters a lot too because it directly affects how much weight the entire truss can handle without sagging or breaking over time. A wrong choice here might mean costly repairs down the road or even safety issues for anyone inside the structure.

A pretty standard component in construction work is what's called a base plate connector, basically designed to spread out the weight properly. Most of these things look like simple flat plates made from steel or other metals that get bolted onto the bottom part of columns or trusses. Their main job? To distribute all that heavy force over a wider area when trusses connect with whatever supports them below ground. Without this kind of dispersion, certain spots might end up taking too much pressure and break down eventually. Anyone working on bigger projects knows how important these connectors really are for keeping everything standing straight, especially in places like big box stores or apartment complexes where the whole structure needs to hold together under constant stress.

The lighting clamp connector stands out as another important type of hardware, mainly for fastening stage lights onto metal frameworks securely. What makes these connectors special is their focus on keeping everything firmly in place so no light fixtures end up crashing down during performances. We see these connectors everywhere from music venues and theater stages right through to trade shows and convention centers where proper illumination matters most. Beyond just holding things up, good quality clamps actually make installation easier while still protecting those heavy duty truss structures from damage over time. A well placed clamp can mean the difference between a smooth show and a dangerous situation waiting to happen.

Applications of Changjianshun Truss Connectors

Truss connectors are pretty important in construction work when it comes to putting together complicated structural designs. Builders use these things all over the place, whether they're working on single family homes or those massive high rise buildings downtown. Take a look at any wood frame house and chances are good there will be truss connectors holding those roof trusses together securely. Without them, the whole structure just wouldn't stand up against Mother Nature's worst weather conditions like strong gusts or torrential downpours. Most experienced contractors know that proper installation of these connectors makes all the difference between a stable home and one that might suffer damage during severe weather events.

When putting together stages and events, truss connectors play a vital role in quickly building temporary structures. Event professionals rely on these connectors to construct everything from basic stages to elaborate lighting systems and overhead frames for concerts, music festivals, and business conferences alike. What makes them so useful is their design that lets crews put things together fast and take them down just as quickly between acts or when moving locations. Imagine trying to build those massive concert stages without them it would take forever and cost a fortune in labor hours. That's why most professional event teams carry a full set of quality truss connectors in their inventory.

Structural stability gets a real boost when truss connectors are properly used, something supported across many different projects and field tests. Take a look at actual construction sites or large events where these connectors make all the difference. Studies indicate that good quality truss systems can improve how weight spreads throughout a structure by around 20 percent, which matters a lot for keeping things safe whether it's a permanent building or just a temporary setup for an event. Beyond preventing collapses, these connectors actually help buildings last longer too. That's why they're becoming standard equipment in both regular construction work and temporary installations like concert stages or exhibition halls.

Review of Changjianshun Truss Connector Products

Changjianshun is renowned for its top-tier truss connectors, including the G44100P and G44T41P models, each offering distinct advantages for diverse applications.

The G44100P Truss Connector stands out as something special in the market thanks to its solid build and quality materials throughout. Built with heavy duty steel components that really hold up over time, this connector delivers consistent performance even when things get tough on site. Contractors love using them for everything from small home renovations to large scale commercial builds because they just work reliably day after day without giving problems. The design handles stress points better than many competitors while maintaining structural integrity during installation processes that can be pretty rough on lesser products.

What makes the G44T41P Truss Connector really special? Let's see. First off, it handles way more weight than standard models while still being simple enough to install even on tight job sites. Contractors love this thing when working on tricky structures where traditional connectors just don't cut it. The design actually addresses those complicated load distribution challenges that come up in modern construction projects. We've seen it perform exceptionally well in bridge reinforcements and large commercial buildings where stability matters most. For anyone dealing with heavy duty applications, this connector delivers the kind of reliability that keeps projects on schedule without compromising safety standards.

These connectors are pivotal not only for their construction efficiency but also for their role in ensuring the safety and integrity of structures, making them invaluable to many projects.

Benefits of Using Changjianshun Truss Connectors

Changjianshun truss connectors make installation much easier than traditional methods. Contractors love working with these because they come with all sorts of handy design elements that cut down on confusion during setup. Most models have those convenient pre-drilled holes already in place along with alignment markers that help everything line up correctly first time around. This means fewer mistakes happen during assembly, so jobs get done faster. And when installations go smoothly without constant adjustments or corrections, it naturally cuts down both labor expenses and the amount of time crews need to spend at each job location.

Changjianshun truss connectors stand out because they work well in so many different situations. From homes to big commercial buildings and even heavy industrial sites, these connectors keep adapting no matter what kind of environment they find themselves in during construction. What makes them special is this ability to handle all sorts of designs and weight demands. Contractors often turn to them when faced with tricky structural challenges where standard solutions just won't cut it. The fact that one connector type can serve multiple purposes saves time and money on site while still delivering solid performance across the board.

Changjianshun truss connectors have proven their safety and durability through extensive testing processes that meet all major industry standards. The design can handle serious stress from both everyday use and harsh weather conditions, so buildings stay strong over many years. These components follow important construction guidelines to stop potential collapses before they happen. Tests in controlled environments as well as actual building sites show that these connectors perform reliably under pressure. Contractors who've used them report fewer issues compared to other brands on the market.

Best Practices for Installing Truss Connectors

Getting truss connectors installed right starts with good prep work. First things first, check those blueprints carefully and double check all materials for any signs of damage or wear before starting. Take accurate measurements and mark exactly where each connector needs to go on the structure. A little extra time here can save headaches later. Don't forget about the workspace itself either. Clear away debris, make sure there's enough lighting, and set up proper safety gear. Working in messy conditions just invites accidents during what should be a straightforward job.

Before starting, gather all the essential tools you will need, including a hammer, nails, safety gloves, and a ladder. These will help you execute the installation process safely and efficiently.

For the step-by-step installation, follow these best practices for optimal results:

- Align the trusses accurately before attaching connectors, ensuring they are flush and level.

- Use the appropriate nails or screws specified by the manufacturer, and apply them at the recommended intervals.

- Secure each connector firmly, but avoid over-tightening which can damage the trusses.

- Inspect the installation to confirm that all connectors are properly secured, ensuring overall stability and safety.

FAQs

What are truss connectors used for in construction?

Truss connectors are used to join truss members together, ensuring the strength and integrity of roofs, floors, and complex structural designs.

Why are Changjianshun truss connectors preferred?

Changjianshun truss connectors are preferred for their superior material quality, durability, ease of installation, and ability to enhance structural integrity and safety.

What types of tools are needed to install truss connectors?

Typical tools include a hammer, nails, safety gloves, a ladder, and, in some instances, a power drill for screws.

Can truss connectors be used for temporary structures?

Yes, they are ideal for temporary structures like stages and event setups due to their quick installation and robust support capabilities.

Recommended Products

Hot News

-

The Application Scenarios Of Lighting Hooks And Trusses

2023-12-14

-

Market Analysis Of Lighting Hooks And Trusses

2023-12-14

-

The Essence Of Lighting Hooks And Trusses

2023-12-14

-

An In-Depth Look At Lamp Hooks And Truss Products

2023-12-14

-

Light Hooks And Truss Products: A Niche But Vital Industry

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA