Truss Clamp and Safety Cable Pairing Tips for Sustainable Stage Installations

How Truss Clamps Distribute Load Across Frameworks

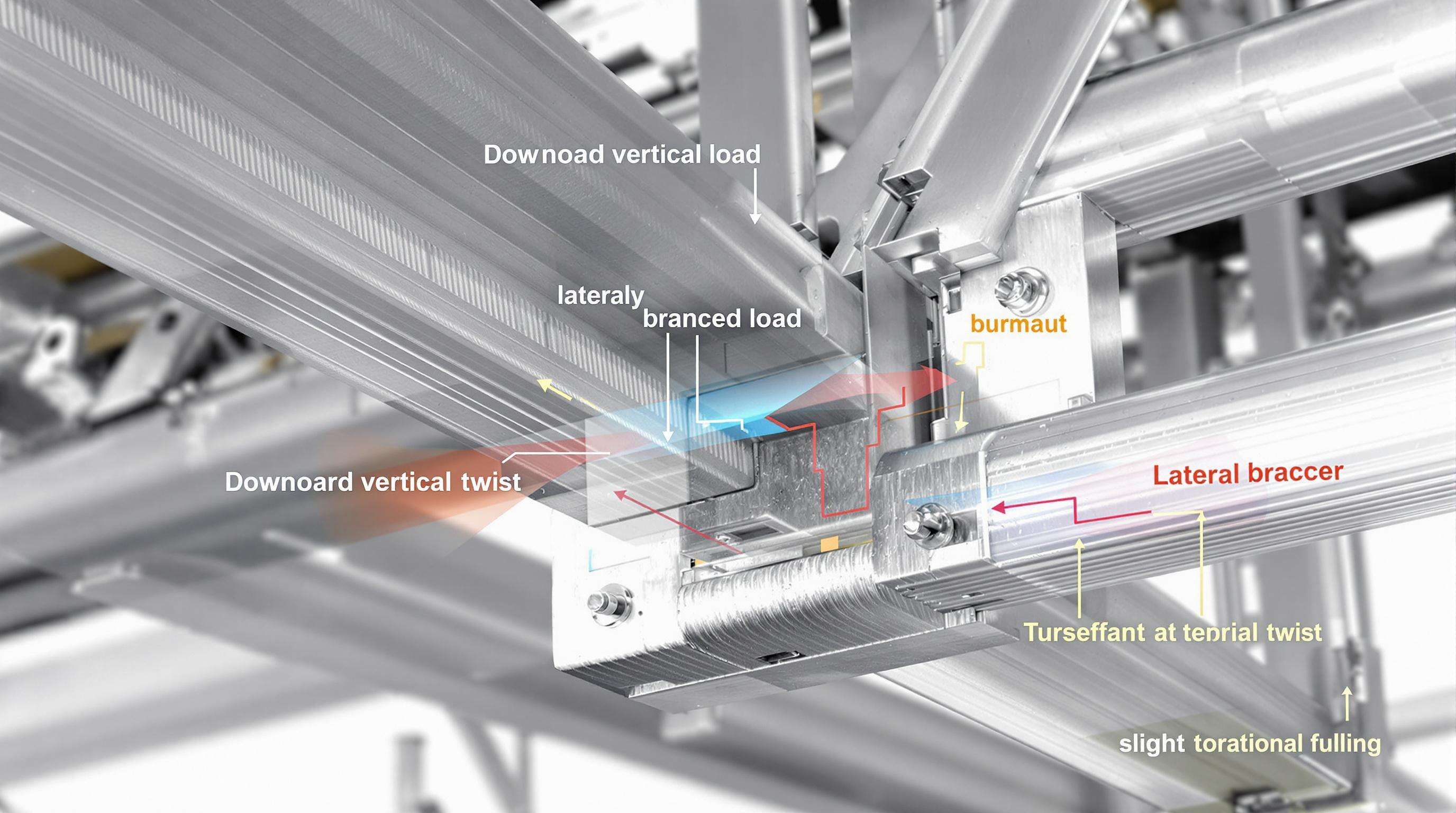

Truss clamps act as force multipliers, transferring equipment weight through three key mechanisms:

- Vertical load channels direct 60-70% of downward forces into primary truss beams

- Lateral bracing absorbs wind/impact shocks via tension-compression coupling

- Torsional resistance counteracts rotational stresses (14-22% of total load in moving installations)

Modern aluminum clamps distribute loads 40% more efficiently than traditional steel models by using ribbed inner surfaces that increase friction coefficients by 0.3-0.5, preventing equipment slippage even under dynamic loads up to 2.5 kN.

Material Standards and Load Ratings in Truss Clamp Design

Leading manufacturers use 6061-T6 aluminum or grade 8.8 steel to meet ISO 9001 and ANSI E1.47 standards:

| Property | Aluminum Clamps | Steel Clamps |

|---|---|---|

| Tensile Strength | 310 MPa | 640 MPa |

| Weight Capacity | 450 kg | 800 kg |

| Corrosion Resistance | Excellent | Moderate |

Load rating certifications require 4:1 safety margins—a clamp rated for 200kg must withstand 800kg before permanent deformation. Annual recertification identifies material fatigue, with studies showing 12% reduced load capacity after 500 setup/teardown cycles.

Compatibility with Truss Systems and Rigging Components

Effective truss clamp integration requires three alignment factors:

- Pin diameter matching (12mm/16mm/20mm standards)

- Clamp jaw depth corresponding to truss chord thickness (±0.5mm tolerance)

- Surface compatibility (anodized aluminum clamps for aluminum trusses; zinc-plated for steel)

Modular systems featuring auto-adjust jaws reduce installation errors by 27% compared to fixed-size clamps by accommodating mixed-material frameworks.

The Essential Role of Safety Cables in Preventing Rigging Failures

Preventing Equipment Fallout with Proper Safety Cable Use

Safety cables serve as a mandatory second line of defense for instances where truss clamps experience unexpected strain or fail to hold. The Event Safety Alliance says venues implementing a mandatory use of safety cable protocols have experienced a decrease in rigging-related incidents by 62%. Installing it properly means mounting its cables to anchor points (structural, not handles or non-load-bearing truss) in a way that ensures they are taut enough to hold on if the equipment falls but loose enough to allow frequent manipulation.

Tensile Strength, Attachment Points, and Load Capacity

Safety cables must match or exceed the tensile strength of the truss clamps they support, with minimum 5:1 safety factors. Key considerations include:

- Attachment compatibility: Use rigging-grade carabiners or shackles

- Load distribution: Anchor cables to primary truss joints

- Environmental factors: Humidity and temperature swings can reduce stainless steel cable strength by up to 15%

Integrating Safety Cables with Moving Head Lights and Dynamic Loads

Moving head lights impose unique challenges, as their pan-tilt motion generates lateral forces that strain clamps and cables. Mitigation strategies include:

- Using braided steel cables with swivel connectors

- Avoiding cable slack which amplifies shock loads

- Inspecting cables every 50 operating hours for fraying or kinking

Optimizing Truss Clamp and Safety Cable Pairing for Load Security

Truss clamps and safety cables form a critical redundancy system for stage rigging. A 2023 study found rigging-related incidents dropped 62% when crews paired properly rated truss clamps with secondary cables rated for 10x the fixture weight.

Synchronizing Rigging Hardware for Balanced Load Distribution

Mismatched components create stress concentrations. Optimal pairing follows:

- Match minimum load ratings between clamps and cables

- Use triangular anchoring patterns to eliminate torsion

- Prioritize galvanized steel or aircraft-grade aluminum hardware

Best Practices for Installing Moving Head Lights on Truss Systems

Moving lights impose dynamic stresses requiring specialized protocols:

| Factor | Static Load Protocol | Dynamic Load Protocol |

|---|---|---|

| Clamp Tightening Torque | 25 Nm | 35 Nm |

| Inspection Frequency | Every 6 months | Every 3 months |

| Cable Redundancy | 1:1 clamp:cable | 2:1 clamp:cable |

Case Study: Lessons from Lighting Rigging Failures

A 2022 concert evacuation incident traced to oversights including:

- Using incorrect grade bolts in clamp assemblies

- Improper safety cable routing

- Uncorrected vibration loosening

Avoiding the Over-Reliance on Truss Clamps Without Secondary Safety Cables

Clamps alone fail to address critical risks like material fatigue, vibration loosening, and human error. Safety cables add crucial failure containment, with modern hybrid cables providing 200% greater energy absorption during sudden load shifts.

Compliance with Rigging Safety Standards and Certification Requirements

Truss clamps must comply with strict guidelines from OSHA and ANSI, including ANSI E1.47's requirement that clamps withstand 5 times their rated load capacity. Failure to adhere increases accident risk by 63%.

Adhering to Load Ratings and Structural Safety Codes

Key protocols include:

- Confirming truss system compatibility

- Avoiding mixed materials to prevent corrosion

- Using stamped load certificates from manufacturers

Inspection, Certification, and Venue Compliance Protocols

Rigging systems require third-party certification every 12 months or after 500 operational hours. Noncompliant systems face immediate shutdowns and average $14,500 fines per OSHA violation.

Sustainable Stage Rigging: Durable Truss Clamps and Reusable Safety Systems

Extending Equipment Lifespan with Proper Safety Cable Maintenance

Regular maintenance like wiping down cables and lubricating swivel points can extend service life by 40-60%.

Reducing Waste Through Modular Trusses and Reusable Hardware

Modular aluminum truss systems eliminate 75% of single-use connectors, while reusable safety cables cut procurement needs by 30% annually.

Environmental Impact of Frequent Rigging Replacements

The industry generates 12,000+ tons of rigging hardware waste yearly—62% from preventable early replacements. Durable clamps rated for 10,000+ load cycles can reduce sector-wide carbon footprints by 18% within five years.

FAQ

What are the main components of a truss clamp system?

A truss clamp system primarily consists of vertical load channels, lateral bracing, and torsional resistance elements. These components jointly manage forces exerted on the truss system.

Why is aluminum preferred over steel for some truss clamps?

Aluminum is often preferred due to its excellent corrosion resistance and lighter weight compared to steel, allowing for easier handling and more efficient load distribution.

What are the safety protocols for using truss clamps?

Safety protocols include ensuring proper clamp alignment, regularly inspecting for material fatigue, utilizing appropriate safety cables, and adhering to compliance standards like those from OSHA and ANSI.

How does a safety cable complement a truss clamp?

Safety cables provide a secondary line of defense, ensuring equipment remains secure if the truss clamp unexpectedly fails, thereby minimizing risk of accidents.

Recommended Products

Hot News

-

The Application Scenarios Of Lighting Hooks And Trusses

2023-12-14

-

Market Analysis Of Lighting Hooks And Trusses

2023-12-14

-

The Essence Of Lighting Hooks And Trusses

2023-12-14

-

An In-Depth Look At Lamp Hooks And Truss Products

2023-12-14

-

Light Hooks And Truss Products: A Niche But Vital Industry

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA