Spigot Truss vs Bolt Truss: Eco-Wise Selection for Global Event Contractors

Spigot Truss: Fast Assembly and Efficiency for Temporary Events

How Spigot Truss Enables Rapid Installation and Dismantling

Spigot Truss systems revolutionize temporary structure assembly through their tool-free design. Built-in connectors allow components to slot together like modular building blocks, eliminating the need for wrenches or specialized hardware. This plug-and-play approach reduces setup times by up to 40% compared to traditional systems.

Key efficiency drivers:

- Precision-cast aluminum joints ensure consistent alignment

- Interlocking spigot mechanism prevents cross-threading errors

- Lightweight 6082-T6 alloy components (35% lighter than steel)

Crews can typically erect a 20-meter truss framework in under 90 minutes – critical for events with tight schedules.

Ideal Use Cases: Concerts, Exhibitions, and Short-Term Setups

The system excels in scenarios requiring frequent reconfiguration:

- Concert tours: Rapid assembly accommodates multi-city schedules

- Trade shows: Modular components adapt to varying booth layouts

- Pop-up installations: Daylight setup for evening events

Industry surveys show 78% of rental companies prioritize spigot systems for exhibitions lasting €3 days due to their inherent flexibility for last-minute changes.

Limitations in Load Capacity and Long-Term Structural Integrity

While optimized for speed, spigot-connected trusses demonstrate 18-22% lower load-bearing capacity than bolt-truss systems. The friction-fit joints:

- Gradually loosen under sustained vibration

- Require re-tightening in windy conditions (>35 km/h)

- Show wear after >15 reuses

These constraints make them unsuitable for:

- Permanent outdoor installations

- Heavy lighting/AV arrays (>700 kg loads)

- Multi-story designs needing seismic resilience

Bolt Truss: Superior Strength and Durability for Demanding Applications

Structural Stability and High Load-Bearing Capacity

Bolt truss systems use industrial-grade fasteners to distribute weight evenly across connections, supporting up to 2,500 kg per linear meter–nearly double spigot system capacity. Bolted frameworks reduce shear stress by 40% compared to friction-fit alternatives, preventing joint slippage under dynamic loads.

Performance in Outdoor, Heavy-Duty, and Semi-Permanent Installations

Engineered for harsh environments, bolt trusses:

- Withstand winds exceeding 120 km/h

- Resist corrosion in coastal/humid settings

- Maintain integrity for years without degradation

Their modularity supports complex geometries like arched stages or multi-tiered exhibition stands.

Long-Term Cost Efficiency

Though assembly takes 25–30% longer than spigot systems, bolt trusses retain 90% of load capacity after 10 years versus 55% for spigot equivalents. This longevity offsets higher initial labor costs for recurring events or permanent installations.

Key Differences Between Spigot Truss and Bolt Truss Systems

| Factor | Spigot Truss | Bolt Truss |

|---|---|---|

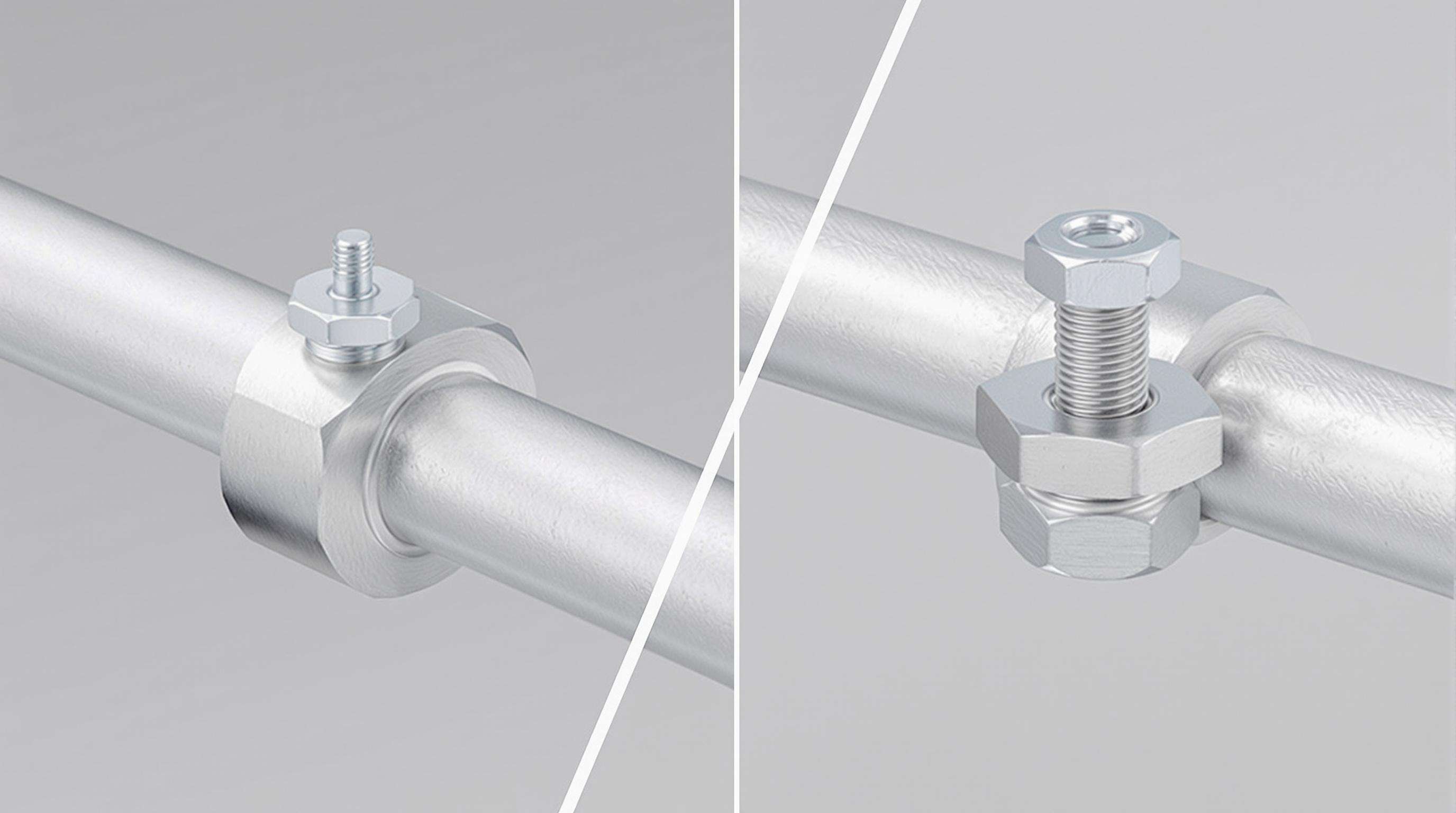

| Joint Type | Friction-fit with pins | Bolted mechanical connection |

| Tools Required | None | Wrenches, torque gauges |

| Material Use | 2-3mm aluminum walls | 3-4mm aluminum walls |

| Load Transfer | Concentrated at pin points | Distributed across bolt array |

Spigot trusses use thinner aluminum walls (6082-T6 grade) for weight reduction, while bolt trusses add reinforcement plates at stress points.

Speed vs. Structural Safety

- Spigot trusses assemble 40% faster

- Bolt trusses offer 740,000 lbs static capacity vs 520,000 lbs

- Bolt systems have 63% fewer field failures

Aluminum Performance and Maintenance

- Spigot joints wear after ~200 insertions

- Bolt trusses use replaceable wear components

- Spigot systems require biannual lubrication

- Bolt trusses need annual thread inspections

Global Industry Trends

83% of EU touring venues mandate bolt trusses for overhead structures. Asian markets show 45% annual growth in bolt truss adoption since updated ISO safety guidelines.

Sustainability and Lifecycle Considerations

Material Efficiency

Aluminum trusses are 100% recyclable, with modern systems incorporating 85% recycled content. Recycling aluminum requires 90% less energy than producing new material.

Carbon Footprint

- Spigot trusses reduce transport emissions by 25% due to lighter weight

- Regional aluminum sourcing cuts embodied carbon by 34%

Reusability vs Energy Use

| Factor | Spigot Truss | Bolt Truss |

|---|---|---|

| Reuse cycles | ~120 | 200+ |

| Recyclability | 98% | 92% |

Bolt trusses excel in semi-permanent installations, while spigot systems are better for frequent transport and reassembly.

Market Trends

- Europe favors bolt trusses for semi-permanent installations

- Asia-Pacific leads spigot truss adoption for pop-up retail

- 73% of North American outdoor venues now mandate bolt trusses for wind resistance

Contractors select systems based on:

- 58% choose bolt truss for 6+ month installations

- 61% switch to bolt systems for heavy AV rigging

- Bolt trusses require 35% fewer inspections over 5 years

FAQ

What is the primary advantage of using spigot truss systems?

Spigot truss systems enable rapid installation and dismantling without the need for tools, which is ideal for temporary events that require quick setup times.

When should bolt truss systems be used?

Bolt truss systems are best for demanding applications that require superior strength and durability, such as heavy-duty outdoor installations or semi-permanent structures.

Are aluminum trusses environmentally friendly?

Yes, aluminum trusses are environmentally friendly as they are 100% recyclable, with many systems incorporating recycled content and reducing energy use compared to new material production.

Which truss type is suitable for frequent transport and reassembly?

Spigot truss systems are better suited for frequent transport and reassembly due to their lightweight construction and ease of setup.

Recommended Products

Hot News

-

The Application Scenarios Of Lighting Hooks And Trusses

2023-12-14

-

Market Analysis Of Lighting Hooks And Trusses

2023-12-14

-

The Essence Of Lighting Hooks And Trusses

2023-12-14

-

An In-Depth Look At Lamp Hooks And Truss Products

2023-12-14

-

Light Hooks And Truss Products: A Niche But Vital Industry

2023-12-14

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

SQ

SQ

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

GA

GA

IS

IS

MK

MK

EU

EU

KA

KA